First Published: October 2021

Quality is a broad concept that can influence the entire culture of a company. In the case of textiles, as far back as the Zhou dynasty in China (B.C. 1046 – B.C. 256), there were quality control measures that prohibited kinds of cotton and silks that didn’t adhere to sizing or quality standards from being sold in marketplaces.

Nowadays, it goes without saying that the quality of products is one of the most important factors for suppliers, manufacturers and consumers. Not only are there compliance and regulatory requirements for most markets to protect consumers and ecosystems but the quality is also critical for ensuring your brand’s reputation in the eyes of the consumer and preventing reputational damage.

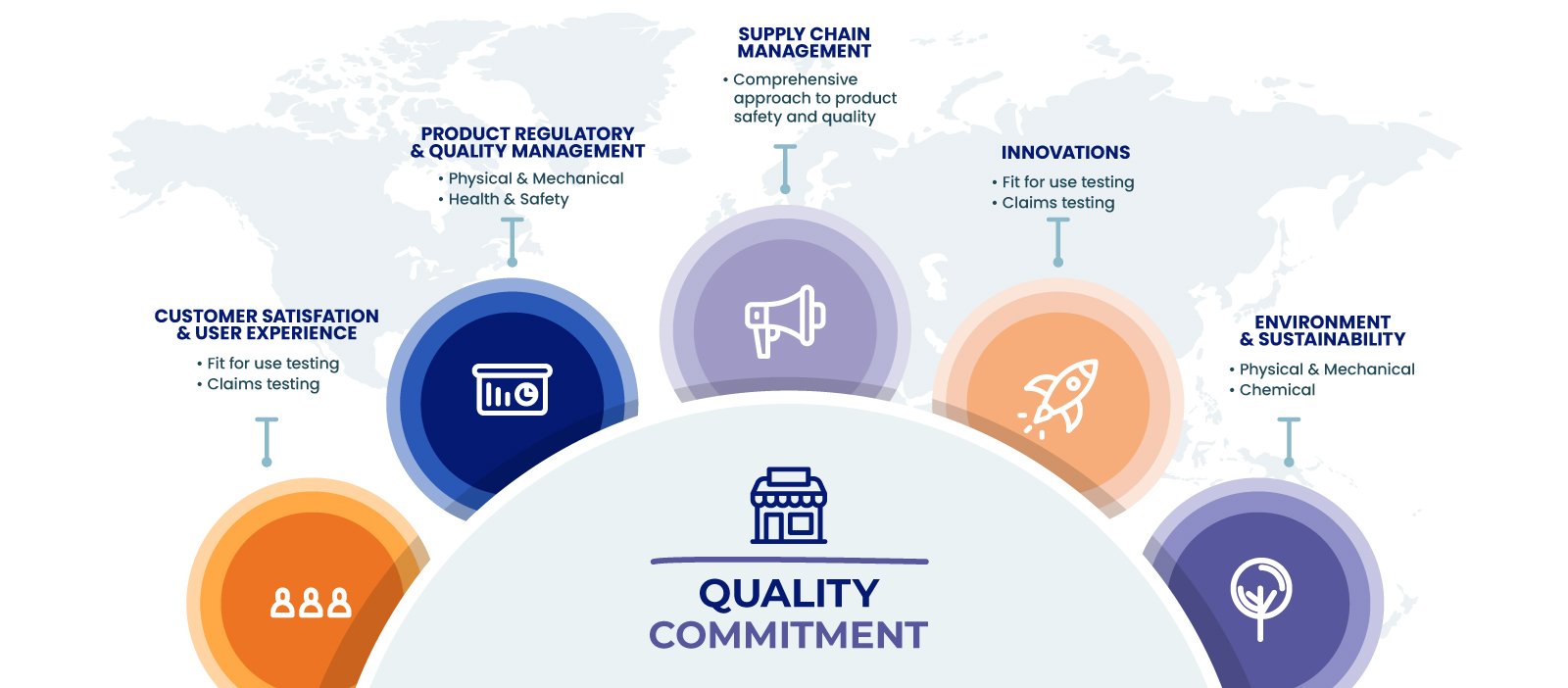

When it comes to the quality commitment you are making as a brand, we like to break it down as below:

The best way brands can make this quality commitment is through testing. In the first of a 3-part series, we take a look at the fundamentals for textile testing when it comes to product regulatory and quality management through mechanical and physical testing.

Physical and mechanical testing for textiles

There are 100s of textile tests that can be performed for fabric and garments but in terms of quality, 6 of the most fundamental are for:

- Tensile strength

- Tear strength

- Seam properties

- Pilling

- Colourfastness

- Dimensional Stability

These tests are mainly to evaluate the textile product’s resistance against mechanical stress, determine the colour resistance against different agents and evaluate the behaviour of the garment when faced with certain treatments.

They provide brands with an idea of how robust the fabric or garment is for product durability and resistance. Let’s take a look at the different textile tests and the reasons for their use in more detail.

Tensile strength

Applicable standards include ISO 13934-1 and ISO 13934-2, with the aim of the test being to assess the strength of a fabric/force required to break a fabric:

- Results interpretation

- Maximum breaking force in N

- % of elongation of fabric before breaking

- Main causes of non-compliance

- Low number of thread counts

- Weak yarns

- Type of fabric/composition

- Recommendation for improvement

- Once fabric is produced, cannot be improved

- Use higher number of thread counts

- Use stronger yarns

Tear strength

Applicable standards include ISO 13937-1, ISO 13937-2, ISO 13937-3 and ISO 13937-4, with the aim of the test being to assess the tear force required to propagate a single-rip tear of defined length from a cut in fabric when a sudden force is applied.

- Results interpretation

- Tearing force in N

- Main causes of non-compliance

- Weak yarns

- Recommendation for improvement

- Once fabric is produced, cannot be improved

- Yarns with longer fibre length

- Yarns with higher twist

- Marginal improvements can be achieved with finishing treatments

Seam properties

Applicable standards include ISO 13936-1, ISO 13936-2 and ISO 13936-3, with the aim of the test being to determine the maximum force application needed to break sewn seams.

- Results interpretation

- Maximum force in N

- Seam opening in mm at a given force

- Main causes of non-compliance

- Stitch type

- Stitch density

- Fabric strength

- Yarn Strength

- Recommendation for improvement

- Change stitch type and/or density

- If problem is fabric, reinforce the seams or change the fabric

- Use a yarn with higher strength

Pilling

Applicable standards include ISO 12945-1 and ISO 12945-2, with the test examining the pilling arising through wear and tear.

- Results interpretation

- 5 – No change

- 4 – Slightly surface fuzzing and partially formed pills

- 3 – Moderate surface fuzzing and moderate pilling

- 2 – Distinct surface fuzzing and distinct pilling

- 1 – Dense surface fuzzing or severe pilling

- Main causes of non-compliance

- Product construction

- Product composition

- Twist number of yarn

- Recommendation for improvement

- Singeing yarn/fabric (to burn loose fibers)

- Increasing the number of twist in yarn

- Fabric finishing (Ploymeric coating)

Colourfastness

Applicable standards include, among others, ISO 105-C06, ISO 105-X11, ISO 105-B02, ISO 105-D01, ISO 105-E01 and ISO 105-E04, with the test being used to evaluate a material’s colour resistance against fading or staining under certain conditions or treatments.

- Results interpretation

- Grey Scales for staining and change in colour from 1 to 5. 1 being very poor and 5 excellent.

- Main causes of non-compliance

- Dyeing/Finishing process

- Dyes used

- Dyes non-appropriate for the material

- Wrong care instructions

- Recommendation for improvement

- Review care instructions

- Increase final rinsing cycles when dyeing

- Use dyes fit for each fiber material

- Use dyes with “high” CF against specific agent

How can Eurofins Softlines & Hardlines help?

As you can see, these 6 textile tests can give you a clear indication of the quality of your garments and apparel. If you would like to know more about how our experts can help with this, get in touch today.

Related Content

Related Article/Webinar Text and Link

Related Article/Webinar Text and Link

Related Article/Webinar Text and Link