Achievement highlights

The Eurofins Assurance QA-QC Team addressed issues in the production of polo shirts at an early stage, successfully reducing the defect rate of collars from 20% to zero. This improvement saved $280,000 by eliminating the high rework costs associated with defective goods.

What was the issue?

Excessive end threads were found at the collars of polo shirts during the quality check of production samples. This defect occurred in approximately 20% of the production samples, accounting for about 5% of the total quantity across 50 containers of goods.

Caption: Photos of protruding threads at collars.

Caption: Photos of protruding threads at collars.

How did we fix it?

Having performed the diagnosis on-site, our QA-QC team identified the cause of collar defect promptly as illustrated above.

Our team picked up the role of Production Engineer of the factory, and re-constructed the production steps of this polo shirt to eliminate the defect:

- The Mending Operators' hiding process has been revised from a one-shot to a two-shot method. With the two-shot technique, the loose end threads can be concealed perfectly within the collar edge tubes. It is common practice in the industry that multiple shots of hiding are required when there are more than two loose end threads on one side, as our team's experience has shown.

- A standard operating procedure (SOP) has been created to document both the hiding and end trimming processes, ensuring that all operators can easily follow the guidelines.

- Mock-up pieces were produced and demonstrated to the operators during a dedicated training session.

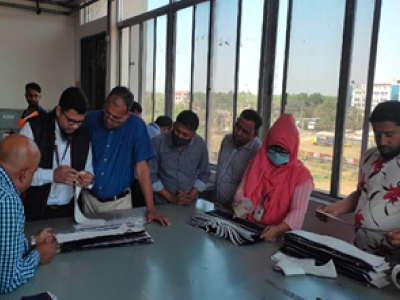

Caption: On-site diagnosis taking place.

Caption: Operators at dedicated training session on two-shot hiding process.

Caption: QC examining collars and whole polo shirts regularly.

What were the results?

It was highly motivating to find that no identical defects were discovered after all the corrective actions were implemented. The defect rate decreased from 20% to zero in the mass production of one million pieces.

If the goods had arrived at the brand’s warehouse, it would have cost at least $280,000 to return and rework them in the country of origin, and then ship the reworked goods back to the market. In addition to this direct expense, potential delays in stock availability for retail and consumer complaints would have resulted in further damage to the brand's reputation and finances.

Eurofins Assurance’s QA-QC program effectively resolved these issues, providing maximum cost-effectiveness that fashion brands and retailers can rely on.

Caption: Polo collar of perfect condition after corrective actions.

Caption: Polo shirt with collar in good condition, ready for sales.

This case underscores the importance of having a Production Engineer in the garment production process, a role that no garment factory should overlook.

Needing a hand in your garment and textile production? Check out how our QA-QC Programme for apparel and garment industry can help!